*IMPORTANT* for administrative purposes our Facebook page has changed, our new *Official* Page and discussion group can now be found here at https://www.facebook.com/35011GSNLRS Please visit and like us to stay connected on Facebook.

Autumn Engineering Update

Autumn Engineering Update

Welcome to this autumn engineering update from the General Steam Navigation project. Progress has been made on various engineering fronts on the project over the past few months and with some of our background efforts about to bear fruit we’ll have some brilliant work to share over the coming months.

Boiler

The boiler tubes are gone! After many months of hard work by our small band of volunteers, the job is done. Work has continued on removing rust from the inside of the firebox, descaling the inside of the boiler, and generally cleaning the inside of the boiler and firebox ahead of a planned inspection later this year. Still to do is sourcing the right tool for removing the thermal-syphon inspection plugs, so that we can wash out the boiler, and then plan the inspection.

Crank axle

Progress with the crank axle has been limited in the past few months; geopolitical events has caused the price of steel to become volatile, after discussions with our friends in the B17 project & A1 Steam Trust, with whom we were planning to place a group order for A4T forgings for the stub axles, we are pausing the ordering process until we have greater certainty over the price. Whilst it is disappointing to not be placing an order for these crucial parts of our locomotive, it feels more prudent to wait, saving us money in the long run. During this self-imposed delay, we are using the time to produce the engineering justification for manufacture of the stub axles in A4T & the sweep webs in 817m40, so that when we are happy with prices, we can proceed.

Frames

Work on the frames continues at a good pace with our volunteers working hard to clean up the frames in preparation for assessment of their condition. With over 50 years of grime to remove on the frames its not a particularly glamorous job but is very important and we are extremely grateful to all our hard workers. We have also removed the brake cylinders from the frames as they wont be required for an original condition Merchant Navy. The cylinders will be cleaned up and stored should a rebuilt Bulleid require them in the future.

Sponsorship component of the month

For those that want to make a more tangible contribution towards putting the steam back in General Steam Navigation we have relaunched the ‘Component Sponsorship’ scheme.

Each month the Society will highlight one particular component. The scheme will allow generous sponsors to cover the cost of individual parts that range from few pounds to several thousands.

Our generous sponsors will receive a certificate describing the part sponsored, be named on the roll of honour on this website and gracious thanks from all those who wish to see General Steam Navigation back in operation.

This month we are starting with the steam chest covers for the outside cylinders. The steam chest covers are a relativity simple component to produce being machined from plate steel. 35011 will require 4 of these in total with the covers being fitted to the front and rear of the cylinder on both sides .The cost of these covers are £250 each. For a full list of the currently available component and how to sponsor them please visit the component sponsorship page.

Draughting

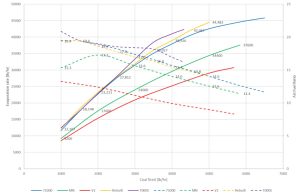

The question that has been asked a few times, both within our project, and outside it, is why we are considering modifications to the exhaust, especially as Bulleid pacifics had a reputation for being free-steaming, if hungry locomotives. The reason is buried in that last statement. Consider how a steam locomotive, especially its combustion system works: exhausting steam in the smokebox produces a draught, sucking air into the firebox for the coal to burn. How much air the locomotive supplies to the fire will impact its fuel combustion. Too little, and you have rich combustion, which releases a lot of heat from the coal, but at the expense of high fuel consumption. Too much air, and you have overly lean combustion, which is cleaner (less production of carbon monoxide), but it can lead to high fuel consumption as well, as the extra air cools the hot air from the fire, reducing the heat transferred to the water in the boiler, meaning more coal is needed to be burnt to produce the same heat transfer to the steam. The reputation, coupled with data from the Rugby reports, suggests that at most of the steaming rates GSN is likely to operate, the combustion is too rich. The perfect air:fuel mass ratio for stochiometric combustion of coal is approximately 11.2:1. It is normal to supply more air than is necessary, to ensure all of the fuel sees sufficient air, normal practise for combustion of coal is to have approximately 30% extra air, so the ratio becomes 14.6:1. Data from the Rugby reports show the original locomotives ran with a ratio of between 11:1 & 17:1, with drop off in performance for steaming rates above 18,000lb/hr, which is where we can expect to operate. The rebuilt design exhaust was much less variable to incomplete combustion, and had higher air:fuel ratio. The data also suggests that these locomotives need to run with significant excess air, far more than the 30% recommendation. The rebuilt design can actually be seen to be broadly similar to how 71000 operated in BR service, suggesting that we can achieve similar performance with 35011 if we can emulate the performance of 71000s twin Kylchap design. By redesigning the exhaust, we should be able to achieve two things: (1) maintain closer to 50% excess air across the power range, reducing fuel consumption and (2) increase the total flow area of the blast nozzles, reducing the cylinder back pressure.

Working Weekends

Our current plan for working weekends  in 2022 is as follows:

in 2022 is as follows:

15th /16th October

12th /13th November

10th /11th December

14th /15th January 2023

11th /12th February 2023

11th /12th March 2023

As always, any members who would be interested in being involved with the engineering of our project, please do get in touch. Our CME Dr Steve Rapley does need some support on the engineering of this project, especially at the moment with weld design, so if you have any experience in this area, please do get in touch. Similarly, if you have any question or comment on the Engineering report or the engineering in general, please do get in touch at by email to Dr Steve Rapley here.

To help us achieve our goal of an original condition Merchant Navy we’ll need your help, you are able to support us in many ways if you are not already a Society member you can sign up for membership for currently only £15 per year here, or donate to the Society here, consider sponsoring a component here or even better become a shareholder here.

As always thank your for your continued support

#OnThisDay the first Atlantic Coast Express ran

#OnThisDay in 1926, the first Atlantic Coast Express ran between London Waterloo and the West Country. Originally named the ”North Cornwall & Bude Express” the service ran from 1907, until, as part of a publicity drive by Southern Railways, the 11 o’clock from Waterloo to the West Country was named the “Atlantic Coast Express” in July 1926. The new name was chosen as the result of a competition run in the staff magazine and the winning entry was submitted by Mr F. Rowland, a guard from Woking who won a prize of three guineas for suggesting Atlantic Coast Express. He was soon to move to Great Torrington in North Devon; he was killed in a shunting accident there six years later. The “Atlantic Coast Express’ very soon became affectionately known to many travellers and enthusiasts as the “ACE”, the shortened version of its full title.

The route was always heavily reliant on holiday passengers which meant that the volume of traffic was very seasonal. On Summer Saturdays, the ACE consisted of up to five trains departing from Waterloo in the 40 minutes before 11:00, stretching resources on the long single-track branch lines to the limit. In the winter timetable, one train was sufficient for all of the branches, and stops were made at all but the most insignificant stations west of Exeter. Significant delays were frequent at the junctions, as coaches were detached or attached and shunted between the various sections of the train, belying the name of “Express”.

In later years, a carriage was detached at Salisbury to join a following stopping train along the main line, and two carriages were detached at Sidmouth Junction, one for Sidmouth and one for Exmouth via Budleigh Salterton. The restaurant and buffet cars were normally removed during the major division at Exeter Central.

Saturdays were always the busiest and in August 1939 the ACE was shown in Bradshaw’s Guide as five separate trains departing from Waterloo; serving Ilfracombe (10:36), Padstow (10:40), Ilfracombe again (10:47), Bude (10:54) and a final departure at 11.00 with portions for Padstow Bude and Plymouth.

Services continued in much the same pattern until the outbreak of World War II, which necessitated longer trains and substantial deceleration on all lines, rendering named trains no longer appropriate.

Putting Funds into the Frames

We have therefore set up a Fund for the Frames that will be essential for the successful restoration of 35011 back into her original condition. Not only do we need to clean and review the condition of the frames as they exist today, any corroded sections of the framework, the rear platform and dragbox will cut out and replaced. We also need to reverse some of the areas that were changed during rebuilding to allow a new middle cylinder to be installed and reinstate Bulleid’s unique patented chain driven valve gear.

This a general fund with no minimum / maximum donation or number of contribution limits, all monies donated to the Fund for the Frames will be specifically ring fenced for the frames. If you are able to contribute to this project in any way however great or small, we thank you for your support.

Questions and Answers with the General Steam Navigation Locomotive Restoration Society

Before our Annual General Meeting earlier in the year some of our directors took the time to answer questions about our project. These questions were put to us by our members and the general public through our social media platforms. So sit back, relax and enjoy this discussion about 35011.

#OnThisDay the first Devon Belle

#OnThisDay in 1947, The “Devon Belle” Pullman service was introduced by the Southern Railway. The service ran between London Waterloo and Ilfracombe with a portion to Plymouth did not in reality last for long as named train services go with the train being ran in September 1954. Usually the train was worked from London to Exeter with Merchant Navy class pacifics and was then split with a four coach portion heading to Plymouth and the remaining eight (sometimes up to ten) coaches including the iconic observation car heading to Ilfracombe both portions usually behind Bulleid Light Pacifics.#

At the time it was the only service to as advertised run ‘non stop’ from Waterloo to Exeter i.e. not stopping at Salisbury, although in reality an unadvertised stop was made at Wilton (the next station to the west of Salisbury) to change engines. This resulted in light engine movements between Wilton and Salisbury in each direction.

To meet the needs of up and down services two Devon Belle rakes were formed along with two popular observation cars on the Ilfracombe portion. These observation cars, numbered 13 and 14, were converted from other coaches, with the origins of No 14 being an ex LNWR Ambulance car which was converted into a Pullman car in 1921 before being ultimately converted for its role as an observation car. With the decline in passenger numbers first the number of operating days was reduced, then from 1950 the Plymouth section ceased and ultimately the final Ilfracombe Devon Belle service was run in September 1954.

Putting Funds into the Frames

We have therefore set up a Fund for the Frames that will be essential for the successful restoration of 35011 back into her original condition. Not only do we need to clean and review the condition of the frames as they exist today, any corroded sections of the framework, the rear platform and dragbox will cut out and replaced. We also need to reverse some of the areas that were changed during rebuilding to allow a new middle cylinder to be installed and reinstate Bulleid’s unique patented chain driven valve gear.

This a general fund with no minimum / maximum donation or number of contribution limits, all monies donated to the Fund for the Frames will be specifically ring fenced for the frames. If you are able to contribute to this project in any way however great or small, we thank you for your support.

Trailing Truck – The Good, The Bad and The Ugly

Since, the last trailing truck update, and arriving at the North Norfolk Railway (NNR) the truck has been fully dismantled, a detailed examination and testing undertaken.

News on the truck can perhaps be broken into 3 sections, The Good, The Bad and The Ugly” (the film being sequel/prequel to “A Fistful of Dollars”, which we need to get the project completed).

The Good

The axle & wheelset are in excellent condition. Visual and Non Destructive Testing (NDT) of the axle showed no defects. One end of the axle has some pitting, but the majority of the axle is at its original size. NNR are awaiting confirmation from Ricardo, our certification body, that we can appoint our preferred subcontractor for the tyre turning/profiling to be done.

The new set of springs that we purchased as part of an order with our friends the 35006 Locomotive Society are excellent and all have the same deflection under load, so setting up the height of the Trailing Truck will be easier.

The Bad

The Left Hand axlebox has visible cracks in three places, one of which extends at least two inches down the side and would need grinding out to near the top of the arch before attempting a welding fix, that being gunmetal could be difficult to demonstrate that it’s been adequately done. The Right Hand axlebox however has no visible cracks. The bottom of both axleboxes are bent, probably from the truck being jacked up at some stage. The LH is far worse than the RH and may well fracture if we try to return it to shape, the RH might be OK to be returned to shape. The plan is to use penetrative dye on both axleboxes to look for further cracks, but there is a good chance we will have to replace the LH axlebox.

There is a pattern available for the axleboxes, and these are the same as for the tender, so if we do decide to replace it, we may well consider ordering all eight to reduce costs (including the RH axlebox).

The Ugly

The swan necks at the front of the truck are in poor condition, especially the Right Hand one. We are recommending that they are cut out completely and replaced as the best long-term solution. We can then be certain the frame remains true, and ensure the strength & rigidity of the final frame. It will also enable NNR to examine the rear of the frame and it’s condition around where the necks are connected.

There is a small crack in the right rear of the frame, close to where the swan neck ends, but it should be repairable. We have instructed NNR to arrange for NDT around the crack, the location on the LHS of the frame and also around all the other weld areas as well, to determine how much material is there and how sound all the welds are.

Next steps

NNR are creating a full CAD of the Trailing Truck, partially to understand how the truck went together originally, as well as for replacement parts. NNR will advise us of the likely costs of the testing and the manufacture and installation of the new swan necks the replacement swan necks . We knew that only once it was fully disassembled, examined and tested that a complete picture of the work required would be obtained.

The support of the members of the Trailing Truck Transformer Fund Club has enabled the substantial amount of progress to date to be achieved. It is likely that the overall cost will exceed the initial estimate for the fund club, even once all ‘Lots’ are allocated and therefore further funding from other sources, such as Company shares will be required. Once again we thank the members for thieir continued support, as mentioned above we do still have further ‘lots’ available in the fund club or alternatively the General Steam Navigation C.I.C. offers all our supporters the opportunity to purchase shares in the locomotive.

The members of the Trailing Truck Transformers group are key to funding this key component back to working order and you can help by joining our group here.

The momentum being generated by our engineering team means 2022 is going to be a very important year for the project with some big goals in mind. To achieve this we will need your help, you are able to support us in many ways if you are not already a Society member you can sign up for membership for currently only £15 per year here, or donate to the Society here or even better become a shareholder here.

Spring Engineering Update

Spring Engineering Update

Boiler

Work continues on the boiler with the last of the remaining boiler tube stubs being removed last month. A big thank you goes out to the sterling work by our volunteers (including Paul G, David O, Geoff A & Jack G) who completed this strenuous task. Work has started on removing rust from the inside of the firebox, descaling the inside of the boiler, and generally cleaning the inside of the boiler and firebox ahead of a planned inspection. It may seem that one paragraph seems like little progress on the boiler, but this work is very labour intensive, and with only a small band of volunteers takes time for the fruit of their labours to become apparent.

Crank Axle

An interesting fact that has come to light recently is clear evidence that the original design for the Merchant Navy had a balanced crank axle. This was mentioned briefly in the Crewkerne report, in going through drawings of the chain- driven valve gear, one early drawing clearly shows a balanced crank axle. There are no other drawings showing this, it is understood that an unbalanced design was introduced to reduce the weight of the locomotive, but it’s interesting to think what could have been, with a balanced crank axle, Crewkerne may never have happened, which was a key driver in the rebuilding process.

Progress on designing the crank axle continues, we have now converted the original drawing into an electronic CAD file. The next step with the axle will be to design the chain-driver sprocket, for which no drawing exists of one that would fit the balanced crank, and to start conversations with a forger & manufacturer to develop forging & manufacturing drawings.

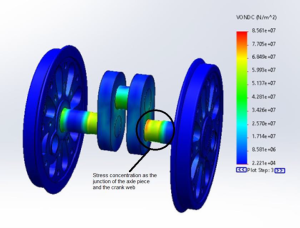

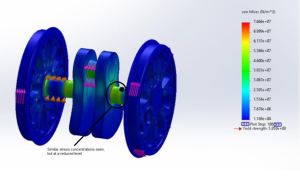

A question of balance

As progress continues with design work for the new crank axle, our thoughts are turning to the balancing design. As members will be aware, one of the changes that was obvious on a rebuilt Merchant Navy were the external balance weights on all 3 axles. Our plan is to remove the weight added in 1958 on the leading & trailing axles and rebalance the wheels with weight in the pockets again, if possible. We still need to decide on the shape & material of the coupling rods, which will impact on the amount of balancing needed on these axles, but aesthetically we want to restore that classic Bulleid appearance with no visible balancing. The central driving axle is another question. Originally the crank webs & inside connecting rod were balanced on the wheel rim, with a large plate on the rear face of the wheels and lead in the pockets. The question that arises is what would have been done to that lead when the balanced design was fitted to 35011 before rebuilding? At first inspection, one would think a significant amount of that lead would have simply been removed. However, it’s slightly more complicated than that. All steam 7 locomotives have an amount of balancing on their wheels, to counteract the rotating masses of the coupling and/or connecting rods, as well as, where necessary, the valve gear. Some locomotives, especially 2-cylinder designs, attempt to partially balance the reciprocating (backwards & forwards) masses, to reduce the front-end oscillation that occurs. This balancing can only be perfectly conducted for a given speed, so the engineer has to decide what speed to balance at, and the percentage of reciprocating masses balanced is usually limited to reduce the hammer-blow on the track from these additional rotating masses. Bulleid reasoned that for a 3-cylinder locomotive the reciprocating masses were to a certain extent self-balanced within the mechanics of the machine, as the longitudinal motion of one cylinder is always partially opposed by the other two, and so didn’t add any additional mass to balance the reciprocating forces. For stability purposes, rotating imbalances on one wheel were balanced on the other, so the left-hand balance weight balances the right-hand motion (and viceversa). By studying & understanding the designs for the original & rebuilt locomotives, we’ve managed to determine how to rebalance the driving axle; it will likely have slightly greater mass (approximately 1062 lbs vs. 942 lbs) on it than on the original design, but it will be at a different location (175° vs 140° from the crank); compared to the rebuilt design the location is similar, but the mass is reduced by around 6%. Geometrically, it can be seen how this works out in the drawing of the original design, by balancing the crank webs with counterweights, we have removed the line labelled middle (GH, the righthand side of the polygon), the closure line is then from A to G & is slightly longer than the line AH, at a shallower angle. The leading & trailing wheels from a mechanical perspective won’t need rebalancing, though from an aesthetic perspective we will plan to do this. We also plan to fit the plain rods that were fitted in 1956, as they have greater tensile strength and are less prone to bending. The next step with the balancing is finer detail; we need to determine the disposition of lead in the pockets to achieve the desired counterbalance. For the leading & trailing wheels, this is little more than a tweak to the original design. The central wheel needs some more design to determine the centre of gravity of the lead pockets and the balance weight plate, it is anticipated this will be completed in the coming weeks.

Frames update

A key event in the process of unrebuilding 35011 occurred at the November working weekend when, with the very welcome assistance of the Swindon & Cricklade Railway, and after many, many weekends of effort, the 5 large brackets that held the external valve gear & screw reverser were lifted off the frames. As we are planning to construct Bulleid’s chain drive valve gear (& fit a steam reverser) these brackets are now surplus to requirements. They are in excellent condition, so we are offering them for sale to any interested parties. By removing these, we made it easier to access other areas of the frame, and quickly removed the last of the brake blocks & arms from the leading & trailing axles. The plan now is to continue 10 removing all the parts hanging off the frames; later in 2022 we should then be able to lift the frames, releasing the leading bogie, leading axle & trailing axle. The leading bogie will then be assessed and prepared for professional restoration to mainline condition, whilst the driving wheels will be sent to South Devon Railway Engineering for rebalancing & profiling.

In order to help fund the work on the frames the Society has started a Funding the Frames appeal that will be essential for the successful restoration of GSN back into her original condition. Not only do we need to clean and review the condition of the frames as they exist today, any corroded sections of the framework, the rear platform and dragbox will cut out and replaced. We also need to reverse some of the areas that were changed during rebuilding to allow a new middle cylinder to be installed and reinstate Bulleid’s unique patented chain driven valve gear.

This a general fund with no minimum / maximum donation or number of contribution limits, all monies donated to the Fundiung the Frames appeal will be specifically ring fenced for the frames. If you are able to contribute to this project in any way however great or small, we thank you for your support. You can find out more here

University projects

We now have a further university project looking at the Internal Aerodynamics of a Merchant Navy. Building on lessons learnt last year, as well as better understanding of the test data that is available on both the original smokebox as well as the rebuilt design, they have made excellent progress simulating 3 baseline designs before moving onto some potential design improvements. The new designs they are looking at include some variations on the original exhaust design as well as variations on a Lempor exhaust, in both cases to understand the impact of nozzle size, angle & target upon the smokebox draught. Based on this work, we may run a final study in academic year 2022/3 to polish off the design as well as to understand how it impacts on the external aerodynamics of the locomotive.

Visit to Great Central & some tender parts

As part of the student project this year, I arranged a visit to Loughborough sheds with the students, to have a crawl around Rebuilt Light Pacific 34039 Boscastle. It was a very useful visit, giving the students a good insight into what they’re simulating, and why, and was also a helpful reminder as to how much pipe work and other gubbins there is on a complete locomotive. Whilst there, in chatting with their Chief Engineer, we were offered some left over parts from their tender for a very reasonable sum, including two front footsteps, two rear footsteps, two rear ladders, one tender tank filler and lid, three Vacuum Reservoir tanks with holding down straps and hardwood timber supports, one Vacuum Reservoir tank cover, one Vacuum Reservoir tank cover, 5 tender doors and two curved front corner pieces. These are all original parts from a 2nd series tender, which became spare when the tender tank was scrapped; the vacuum reservoirs are the wrong type for a Light Pacific, the footsteps & ladders were going to be reused but were inadvertently reordered as part of the manufacture of the tank. Whilst we are years from constructing our tender, and still need to flesh out our ideas for it, it is nice to be able to have some genuine parts that can one day be fitted to our machine.

We have also recently managed to purchase two electrical lamps for the locomotive, so we now have 6 lamps. The purchase of one was sponsored by one of our directors, but if you would like to sponsor the other, please do get in touch with us.

Other Engineering Progress

We have made a start on two other big engineering areas in the last few months. Firstly, members of the Engineering Sub-Committee have started creating an online Engineering Bill of Materials (EBoM). As members of the Bulleid Pacific Locomotives Association, we have access to the extensive collection of over 3000 drawings in their catalogue, but the way they are catalogued is not very easy for understanding the relationship between the drawings, nor for knowing what drawings we are missing. By producing the EBoM, in time we will be able to have a clear record of how many of each part we need, the drawings for them, records of when we order parts & how, records of manufacture where appropriate, etc. Those projects that have constructed (or are constructing) locomotives from scratch, such as 60163, 2007, 72010 have gone through a similar 13 process. By starting this, we are laying the foundations for our original Merchant Navy and starting to put the documentation in place we will need to be accepted for mainline running.

We have made a start on two other big engineering areas in the last few months. Firstly, members of the Engineering Sub-Committee have started creating an online Engineering Bill of Materials (EBoM). As members of the Bulleid Pacific Locomotives Association, we have access to the extensive collection of over 3000 drawings in their catalogue, but the way they are catalogued is not very easy for understanding the relationship between the drawings, nor for knowing what drawings we are missing. By producing the EBoM, in time we will be able to have a clear record of how many of each part we need, the drawings for them, records of when we order parts & how, records of manufacture where appropriate, etc. Those projects that have constructed (or are constructing) locomotives from scratch, such as 60163, 2007, 72010 have gone through a similar 13 process. By starting this, we are laying the foundations for our original Merchant Navy and starting to put the documentation in place we will need to be accepted for mainline running.

The second significant progress is in the subject of assurance, the process by which we demonstrate the locomotive meets the standards necessary for mainline running. After meetings with numerous potential assurance partners, and independent advice from others in the industry, we have appointed Ricardo Rail to be our assurance partner. They will give us the support to understand & produce the evidence we need to restore General Steam Navigation to original design conditions whilst meeting mainline standards, and document that process. They work with numerous similar projects and are a good fit for our project.

Finally, we are becoming involved in a forum of new-build steam locomotives, to look at ways of pooling knowledge and cost-saving between us. Whilst that title may bring howls of protest from some quarters, we have things we can learn from these groups in the assurance process. Where we are manufacturing components from scratch, we will need to demonstrate that the finished component doesn’t bring additional risk to the design compared to the original. Where we are restoring, we will need to demonstrate that our restoration has returned the components to a condition where it doesn’t bring additional risk to the locomotive.

As always, any members who would be interested in being involved with the engineering of our project, please do get in touch. I need some support on the engineering of this project, especially at the moment with weld design, so if you have any experience in this area, please do get in touch. We also need some additional support archiving drawings online into the EBoM, this is an opportunity to study some of the original drawings of a Bulleid pacific. Similarly, if you have any question or comment on the Engineering report or the engineering in general, please do email our CME (steve.rapley@35011gsn.co.uk)

The momentum being generated by our engineering team means 2022 is going to be a very important year for the project with some big goals in mind. To achieve this we will need your help, you are able to support us in many ways if you are not already a Society member you can sign up for membership for currently only £15 per year here, or donate to the Society here or even better become a shareholder here.

As always thank you for your continued support.

March 2022 Update

March 2022 Update

March 2022 Update

The Packet

Issue 17 of our Member’s magazine The Packet should, subject to local post, have arrived with our members. We hope all members enjoy the comprehensive 32 page read getting the latest updates on the great progress being made on the restoration of GSN.

If you are not yet a member and therefore missing out you can join us here https://www.35011gsn.co.uk/membership.html

2022 Annual General Meeting

The sixth Annual General Meeting of the Society will be held on Sunday 15th May at Blunsdon on the Swindon and Cricklade Railway at 1pm. This years AGM will be taking place on an operational day for the Swindon and Cricklade allowing members to have the first opportunity to experience all the line has to offer before the meeting. Catering facilities will also be available in the railways excellent onsite café. The AGM is still dependent on Governmental guidance. The AGM will be the first that many of you will have had the chance to get to see the engine following her boiler lift in the Autumn 2019 and the major work that has continued since that time. It is planned that once the society AGM has been completed the CIC’s will take place with the shareholders. Shareholders will be contacted separately in this matter.

Volunteer Opportunities

Our working parties are attended by dedicated and enthusiastic volunteers, despite recent Covid restrictions, who also take the time to man our sales stand at various railway events that helps not only raise funds but also continues to spread the word about our project. Much work has taken place behind the scenes during the last 12 months, particularly on the engineering and fundraising fronts. This good work will soon hopefully bear fruit and with this in mind we plan to accelerate the rate of GSNs restoration and expand the number of railways we visit with our sales stand and also further increase both number of working parties and the number of volunteers that can work on site at any one time.

To further strengthen owning CIC and Society boards we are looking for somebody with relevant legal experience to act in an advisory capacity when required. This would not be an onerous task or overly time consuming but would be a very useful addition to our team. To enable our engineering progress to step up a gear the Society does need to increase its income and anyone with fundraising experience or ideas would be extremely useful to the project.

In the same way we are also looking for an advisor with experience of reviewing and drafting engineering / purchasing contracts to assist us when sending parts away for contract overhaul & such like. Our CME Dr Steve Rapley is doing fantastic work on planning, researching, parts design and all mechanical matters relating to the overhaul, he is assisted by an engineering subcommittee and would like to recruit additional volunteers with solid engineering experience or qualifications (professional welding knowledge would be particularly useful) to assist him leading the engineering team & turn our dreams into reality.

Finally, if you fancy helping us either with the restoration at Blunsdon or helping take our sales stand to major steam events around the county you would be made most welcome. Our working parties are friendly affairs with much laughter as well as satisfying work on the loco, new members are always welcome to join our happy family. If you are interested in any of the roles mentioned above, then please get in touch with myself at andrew.collett@35011gsn.co.uk and we will look forward to welcoming you to our friendly team. With your help 2022 will see us increase the rate of restoration and fund raising and be a year closer to putting the steam back into General Steam Navigation.

Fundraising Coach Trip

Following the success of our 2021 fundraising trip to Yorkshire we are planning a similar trip in 2022, with profits again being split between GSN & the S&CR.

The trip departs on Monday30th May & is 4 nights half board. We are staying at the TLH Victoria Hotel in Torquay which is close to both the seafront and town centre, the proposed itinerary is a follows:

- Day One. We depart Blunsdon & travel to Torquay.

- Day Two Return journey on the South Devon Steam railway from Buckfastleigh to Totnes.

- Day Three. We travel into Cornwall and ride on the steeply graded Bodmin & Wenford Steam Railway.

- Day Four. Return journey on the Paignton & Dartmouth Steam Railway.

- Day Five. We return home with stops en route.

We hope you join us for a steam filled week. A great way to raise money and meet fellow members and volunteers. The cost is from £459pp and includes all travel and train fares and 4 nights half board accommodation.

Please contact Holidays & Cruises in Melksham on 01225 865725 to book your place.

Fundraising Wagons

The Society still has a number of fundraising wagons available for sale. The model has been produced by Dapol and is based on their 00 gauge 7 plank open wagons with the lettering General Steam Navigation, Blunsdon & Gillingham Pier (the locations of the two Societies) and Number 22. The wagon is available in either black or green, both colours that were carried by 21c11 General Steam Navigation during her lifetime. The wagons include a coal load.

A small number of the previous limited edition N Gauge Gun Powder Vans in either red or blue are also still available for £11.90 whilst stocks last.

Become a shareholder in 35011

The General Steam Navigation C.I.C. is offering our supporters the

opportunity to purchase shares or additional shares in the locomotive. Shares are sold in blocks of 250 by £1 which can be purchased directly, via standing order (£25 a month for 10 months) or online.

What will you get for your money?

• Choice of 1 of 3 Stuart Black exclusive portraits of General Steam

Navigation in her various conditions

• One Ticket behind General Steam Navigation’s first passenger

service

• First choice of components to sponsor

• Invitation to our yearly shareholders day and all open workshop

events

For members who purchase more than one block the Company has

created some extra rewards.

500 Shares

• Tickets for four people to ride on General Steam Navigation’s first

passenger service

• The remaining 2 Stuart Black portraits to add to your collection

1000 Shares

• Footplate ride on General Steam Navigation

2500 Shares

• Name engraved on the roll of honour plate inside General Steam

Navigation’s cab

• Chance to drive General Steam Navigation

• Free Society Membership for five years

To apply for shares please visit our shareholders page on the website.

A full engineering report will be appearing the next few weeks, until then thank you for your continued support.

35011 Component Sponsorship Opportunity

The Society would like to order 2 new sets of springs for the Trailing Truck as part of a group order with another Merchant Navy. The first set will be used on the trailing truck straight away with the second set being kept as spares for when the engine is running. Costing £175 each these 8 springs are on the lower end of the price range for components that can be easily seen from the outside of the locomotive. If one day you’d like to be standing next to a fully restored General Steam Navigation and have the ability to point and say “I paid for those” these springs could be the perfect opportunity for you. If you are interested, please do email our sponsorship co-ordinator at Simon.Shutt@35011GSN.co.uk

Thank you

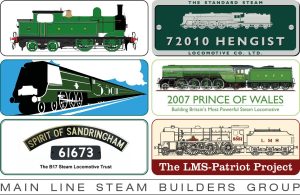

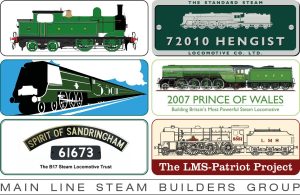

New Mainline Steam Builders Group starts work

The General Steam Navigation Locomotive Restoration Society is one of six high-profile steam project groups with the common objective of delivering their respective locomotives fit for UK mainline running that have agreed to meet and cooperate with each other on a regular basis.

While the groups all have their own technical and project management challenges to deal with, many of the present-day safety certification and related requirements are to some degree of a generic nature, applicable to all new or restored steam locomotives. Group members can also build on the collective knowledge in the new build sector, and the significant experience / expertise gained by the A1 Trust through the previous approval of Tornado; helping each other by sharing information and experience. While the main focus will be on meeting the risk management and network compatibility requirements of the rail industry safety certification standards, other directly related issues (for example supplier assurance, technical solutions) will be under discussion. Sharing third party costs where appropriate can ease pressure on individual project budgets.

Founder Group Members are:

B17 Steam locomotive Trust

Class G5 Locomotive Company

General Steam Navigation Locomotive Restoration Society

LMS-Patriot Company

P2 Steam Locomotive Company (A1 Steam Locomotive Trust)

Standard Steam Locomotive Company (72010 Hengist)

The Group decided to come together as the benefits became clear through their individual project experiences.

An inaugural meeting was held on 26th January 2022 at the premises of CTL Seal Ltd, a large bespoke engineering company in Sheffield that is now the home of the B17 and Hengist projects. With the expert guidance of Graham Nicholas from the P2 project (sharing direct experience from the A1 project and his work for the Railway Safety Standards Board), along with representatives of Ricardo Certification Ltd, the group studied the evolution of rail industry certification requirements up to the present day, before starting work together on a hazard identification exercise for heritage steam locomotive design and manufacture / restoration.