Autumn Engineering Update

Welcome to this autumn engineering update from the General Steam Navigation project. Progress has been made on various engineering fronts on the project over the past few months and with some of our background efforts about to bear fruit we’ll have some brilliant work to share over the coming months.

Boiler

The boiler tubes are gone! After many months of hard work by our small band of volunteers, the job is done. Work has continued on removing rust from the inside of the firebox, descaling the inside of the boiler, and generally cleaning the inside of the boiler and firebox ahead of a planned inspection later this year. Still to do is sourcing the right tool for removing the thermal-syphon inspection plugs, so that we can wash out the boiler, and then plan the inspection.

Crank axle

Progress with the crank axle has been limited in the past few months; geopolitical events has caused the price of steel to become volatile, after discussions with our friends in the B17 project & A1 Steam Trust, with whom we were planning to place a group order for A4T forgings for the stub axles, we are pausing the ordering process until we have greater certainty over the price. Whilst it is disappointing to not be placing an order for these crucial parts of our locomotive, it feels more prudent to wait, saving us money in the long run. During this self-imposed delay, we are using the time to produce the engineering justification for manufacture of the stub axles in A4T & the sweep webs in 817m40, so that when we are happy with prices, we can proceed.

Frames

Work on the frames continues at a good pace with our volunteers working hard to clean up the frames in preparation for assessment of their condition. With over 50 years of grime to remove on the frames its not a particularly glamorous job but is very important and we are extremely grateful to all our hard workers. We have also removed the brake cylinders from the frames as they wont be required for an original condition Merchant Navy. The cylinders will be cleaned up and stored should a rebuilt Bulleid require them in the future.

Sponsorship component of the month

For those that want to make a more tangible contribution towards putting the steam back in General Steam Navigation we have relaunched the ‘Component Sponsorship’ scheme.

Each month the Society will highlight one particular component. The scheme will allow generous sponsors to cover the cost of individual parts that range from few pounds to several thousands.

Our generous sponsors will receive a certificate describing the part sponsored, be named on the roll of honour on this website and gracious thanks from all those who wish to see General Steam Navigation back in operation.

This month we are starting with the steam chest covers for the outside cylinders. The steam chest covers are a relativity simple component to produce being machined from plate steel. 35011 will require 4 of these in total with the covers being fitted to the front and rear of the cylinder on both sides .The cost of these covers are £250 each. For a full list of the currently available component and how to sponsor them please visit the component sponsorship page.

Draughting

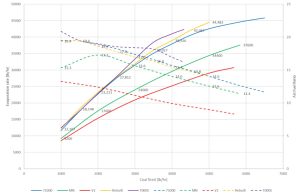

The question that has been asked a few times, both within our project, and outside it, is why we are considering modifications to the exhaust, especially as Bulleid pacifics had a reputation for being free-steaming, if hungry locomotives. The reason is buried in that last statement. Consider how a steam locomotive, especially its combustion system works: exhausting steam in the smokebox produces a draught, sucking air into the firebox for the coal to burn. How much air the locomotive supplies to the fire will impact its fuel combustion. Too little, and you have rich combustion, which releases a lot of heat from the coal, but at the expense of high fuel consumption. Too much air, and you have overly lean combustion, which is cleaner (less production of carbon monoxide), but it can lead to high fuel consumption as well, as the extra air cools the hot air from the fire, reducing the heat transferred to the water in the boiler, meaning more coal is needed to be burnt to produce the same heat transfer to the steam. The reputation, coupled with data from the Rugby reports, suggests that at most of the steaming rates GSN is likely to operate, the combustion is too rich. The perfect air:fuel mass ratio for stochiometric combustion of coal is approximately 11.2:1. It is normal to supply more air than is necessary, to ensure all of the fuel sees sufficient air, normal practise for combustion of coal is to have approximately 30% extra air, so the ratio becomes 14.6:1. Data from the Rugby reports show the original locomotives ran with a ratio of between 11:1 & 17:1, with drop off in performance for steaming rates above 18,000lb/hr, which is where we can expect to operate. The rebuilt design exhaust was much less variable to incomplete combustion, and had higher air:fuel ratio. The data also suggests that these locomotives need to run with significant excess air, far more than the 30% recommendation. The rebuilt design can actually be seen to be broadly similar to how 71000 operated in BR service, suggesting that we can achieve similar performance with 35011 if we can emulate the performance of 71000s twin Kylchap design. By redesigning the exhaust, we should be able to achieve two things: (1) maintain closer to 50% excess air across the power range, reducing fuel consumption and (2) increase the total flow area of the blast nozzles, reducing the cylinder back pressure.

Working Weekends

Our current plan for working weekends  in 2022 is as follows:

in 2022 is as follows:

15th /16th October

12th /13th November

10th /11th December

14th /15th January 2023

11th /12th February 2023

11th /12th March 2023

As always, any members who would be interested in being involved with the engineering of our project, please do get in touch. Our CME Dr Steve Rapley does need some support on the engineering of this project, especially at the moment with weld design, so if you have any experience in this area, please do get in touch. Similarly, if you have any question or comment on the Engineering report or the engineering in general, please do get in touch at by email to Dr Steve Rapley here.

To help us achieve our goal of an original condition Merchant Navy we’ll need your help, you are able to support us in many ways if you are not already a Society member you can sign up for membership for currently only £15 per year here, or donate to the Society here, consider sponsoring a component here or even better become a shareholder here.

As always thank your for your continued support