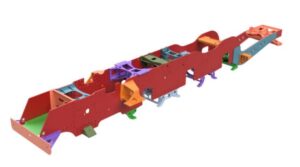

Work on General Steam Navigation has progressed at a pace over the last few months with our regular working parties at Blunsdon. The majority of the work has been focused around 35011s chassis in preparation for “crane day” that happened in November. With the help of our friends at the Swindon and Cricklade Railway steam department our volunteers were able to successfully remove the five frame hangers that won’t be required in the restoration of General Steam Navigation back to Bulleid’s original condition.

These components were: the slidebar bracket hangers (these were heavily modified upon rebuilding due to the outside valve gear) and outside motion brackets on each side; along with the screw reverser bracket on the left hand side.

In the spring of next year it is planned to remove 35011s remaining wheels and front bogie in order to enable a full assessment of her frames to be undertaken.

Preparation work for producing the components required for the chassis and the alternations to the existing metalwork is being undertaken at the moment. This will enable the work to restore the rolling chassis to be only limited by the amount of money that can be raised to pay for the work. To help this work the Society has set up a “Putting Funds into the Frames” appeal which enables people to donate as little or as much to the project with the guarantee that it’ll be spent on the frames. You can find out more here.

Supporters will be aware that when we lifted the boiler from the frames in October last year, we also lifted the rear of the frames to release the Trailing Truck. Since then, work has been undertaken to remove the majority of the components that make up the Trailing Truck.

Following an independent assessment, we undertook a competitive tender process and in August we awarded the contract for the full refurbishment, and certification of the Trailing Truck by specialist contractors North Norfolk Railway Engineering (NNE).The Trailing Truck left Blunsdon and arrived safely at NNE Weybourne on the 10th October.

Since then North Norfolk Engineering have provided the following update of their activities:

• Completed the dismantling of the main component parts, with the truck chassis now lifted off the wheelset in readiness for the complete set of main parts and wheelset being sent away for shot blasting.

• Undertaken a series of key dimensional measurements to assess the general condition and wear levels ahead of developing the engineering overhaul strategy.

• Removed the seized main pivot pin out from its bronze bush and assessed the reason for it seizing, as the bush appears has moved during its working life and rotated in the frame boss, blanking off the grease hole in the process, reducing lubrication.

The next key stage is to undertake Ultrasonic Axle Testing (UAT) of the axle and the axle to wheel interfaces to verify that no flaws are present. It will be carried out by a Rail Industry approved axle specialist early in the new year (at the same time as the annual check of all locomotives on the North Norfolk Railway to minimise cost).We are in the process of arranging the purchasing new suspension coil springs and are currently working with various suppliers. To help fund the restoration of the trailing truck the Society is offering a maximum of 30 members the opportunity to purchase a ‘Lot’ for £500. Members are welcome to purchase as many ‘Lots’ as they wish up to the maximum target amount.

Members of the Fund Group would receive a number of benefits including:

- Certificate of membership of the ‘Trailing Truck Transformers’

- Name engraved on a suitable brass plaque attached to the refurbished Trailing Truck

- Regular updates on the refurbishment of the Trailing Truck

- An invitation to a VIP day at the Swindon and Cricklade Railway to see the completed Trailing Truck once it is returned to the railway.

For details on how to become a Trailing Truck Transformer please click here.

In November our CME Dr Steve Rapley took a group of students from Loughborough University to look at the smokebox and exhaust of 34039 Boscastle. This was to aid their understanding of the geometry they’re studying as part of developing the Internal Aerodynamics and draughting of 335011 General Steam Navigation Locomotive Restoration Society. The Society would like thank Andy Morgan and Mike for hosting us.

Progress continues with the boiler, there are still some stubborn ends of tubes to remove, but it is down to a handful now. Sterling work by our volunteers (including Paul G, David O, Geoff A & Jack G) continues with this strenuous task, with the expectation that the remainder will be out in the coming months. Work has started on removing rust from the inside of the firebox, and generally cleaning the inside of the boiler and firebox ahead of a planned inspection early next year. It may seem that one paragraph seems like little progress on the boiler, but this work is very labour intensive, and with only a small band of volunteers, maintaining Covid safe practices, it takes time for the fruit of their labours to become apparent.

In order to keep moving forwards with our restoration activities, the society is looking for a qualified railway mechanical engineer, preferably with welding experience or weld design experience, to advise the CME & Engineering Sub-committee in this field. If you fit this description, or know someone who does, please get in touch with us via info@35011gsn.co.uk

The momentum being generated by our engineering team means 2022 is going to be a very important year for the project with some big goals in mind. To achieve this we will need your help, you are able to support us in many ways if you are not already a Society member you can sign up for membership for currently only £15 per year here, or donate to the Society here or even better become a shareholder here.

As always thank you for your continued support.

Originally fitted to a series 3 Merchant Navy, our fabricated trailing truck is the last survivor of its kind. Lighter than the cast truck fitted to the other preserved Merchant Navy locomotives, longer than a Light Pacific’s truck, the GSNLRS are having this unique piece of Bulleid locomotive design restored to mainline standard, a crucial step towards GSNLRS’s vision of an original Merchant Navy with original air smoothed casing and Bulleid’s patented chain driven valve gear.

Originally fitted to a series 3 Merchant Navy, our fabricated trailing truck is the last survivor of its kind. Lighter than the cast truck fitted to the other preserved Merchant Navy locomotives, longer than a Light Pacific’s truck, the GSNLRS are having this unique piece of Bulleid locomotive design restored to mainline standard, a crucial step towards GSNLRS’s vision of an original Merchant Navy with original air smoothed casing and Bulleid’s patented chain driven valve gear.